Design for Sustainability: New Design Principles for Reducing IT Hardware Emissions

- We’re presenting Design for Sustainability, a set of technical design principles for new designs of IT hardware to reduce emissions and cost through reuse, extending useful life, and optimizing design.

- At Meta, we’ve been able to significantly reduce the carbon footprint of our data centers by integrating several design strategies such as modularity, reuse, retrofitting, dematerialization, using greener materials, and extended hardware lifecycles, Meta can significantly reduce the carbon footprint of its data center infrastructure.

- We’re inviting the wider industry to also adopt the strategies outlined here to help reach sustainability goals.

The data centers, server hardware, and global network infrastructure that underpin Meta’s operations are a critical focus to address the environmental impact of our operations. As we develop and deploy the compute capacity and storage racks used in data centers, we are focused on our goal to reach net zero emissions across our value chain in 2030. To do this, we prioritize interventions to reduce emissions associated with this hardware, including collaborating with hardware suppliers to reduce upstream emissions.

What Is Design for Sustainability?

Design for Sustainability is a set of guidelines, developed and proposed by Meta, to aid hardware designers in reducing the environmental impact of IT racks. This considers various factors such as energy efficiency and the selection, reduction, circularity, and end-of-life disposal of materials used in hardware. Sustainable hardware design requires collaboration between hardware designers, engineers, and sustainability experts to create hardware that meets performance requirements while limiting environmental impact.

In this guide, we specifically focus on the design of racks that power our data centers and offer alternatives for various components (e.g., mechanicals, cooling, compute, storage and cabling) that can help rack designers make sustainable choices early in the product’s lifecycle.

Our Focus on Scope 3 Emissions

To reach our net zero goal, we are primarily focused on reducing our Scope 3 (or value chain) emissions from physical sources like data center construction and our IT hardware (compute, storage and cooling equipment) and network fiber infrastructure.

While the energy efficiency of the hardware itself deployed in our data centers helps reduce energy consumption, we have to also consider IT hardware emissions associated with the manufacturing and delivery of equipment to Meta, as well as the end-of-life disposal, recycling, or resale of this hardware.

Our methods for controlling and reducing Scope 3 emissions generally involve optimizing material selection, choosing and developing lower carbon alternatives in design, and helping to reduce the upstream emissions of our suppliers.

For internal teams focused on hardware, this involves:

- Optimizing hardware design for the lowest possible emissions, extending the useful life of materials as much as possible with each system design, or using lower carbon materials.

- Being more efficient by extending the useful life of IT racks to potentially skip new generations of equipment.

- Harvesting server components that are no longer available to be used as spares. When racks reach their end-of-life, some of the components still have service life left in them and can be harvested and reused in a variety of ways. Circularity programs harvest components such as dual In-line memory modules (DIMMs) from end-of-life racks and redeploy them in new builds.

- Knowing the emissions profiles of suppliers, components, and system designs. This in turn informs future roadmaps that will further reduce emissions.

- Collaborating with suppliers to electrify their manufacturing processes, to transition to renewable energy, and to leverage lower carbon materials and designs.

These actions to reduce Scope 3 emissions from our IT hardware also have the additional benefit of reducing the amount of electronic waste (e-waste) generated from our data centers.

An Overview of the Types of Racks We Deploy

There are many different rack designs deployed within Meta’s data centers to support different workloads and infrastructure needs, mainly:

- AI – AI training and inference workloads

- Compute – General compute needed for running Meta’s products and services

- Storage – Storing and maintaining data used by our products

- Network – Providing Low-latency interconnections between servers

While there are differences in architecture across these different rack types, most of these racks apply general hardware design principles and contain active and passive components from a similar group of suppliers. As such, the same design principles for sustainability apply across these varied rack types.

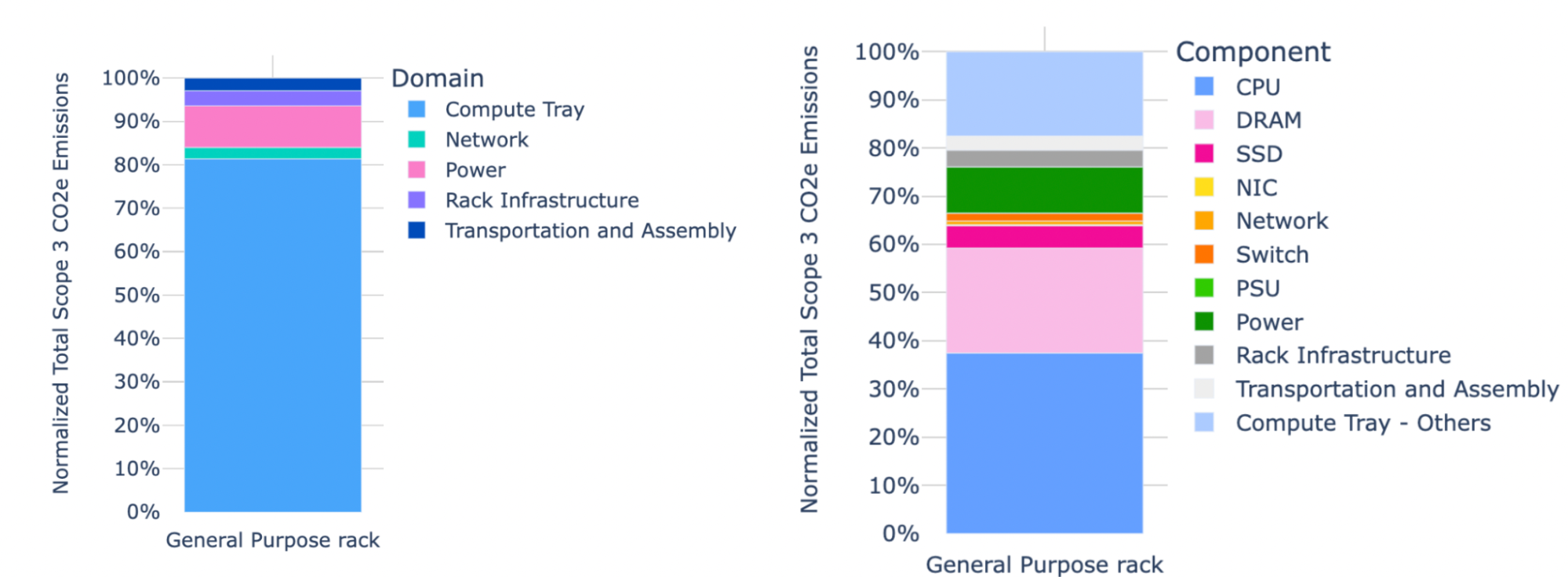

Within each rack, there are five main categories of components that are targeted for emissions reductions:

- Compute (i.e., memory, HDD/SSD)

- Storage

- Network

- Power

- Rack infrastructure (i.e., mechanical and thermals)

The emissions breakdown for a generic compute rack is shown below.

Our Techniques for Reducing Emissions

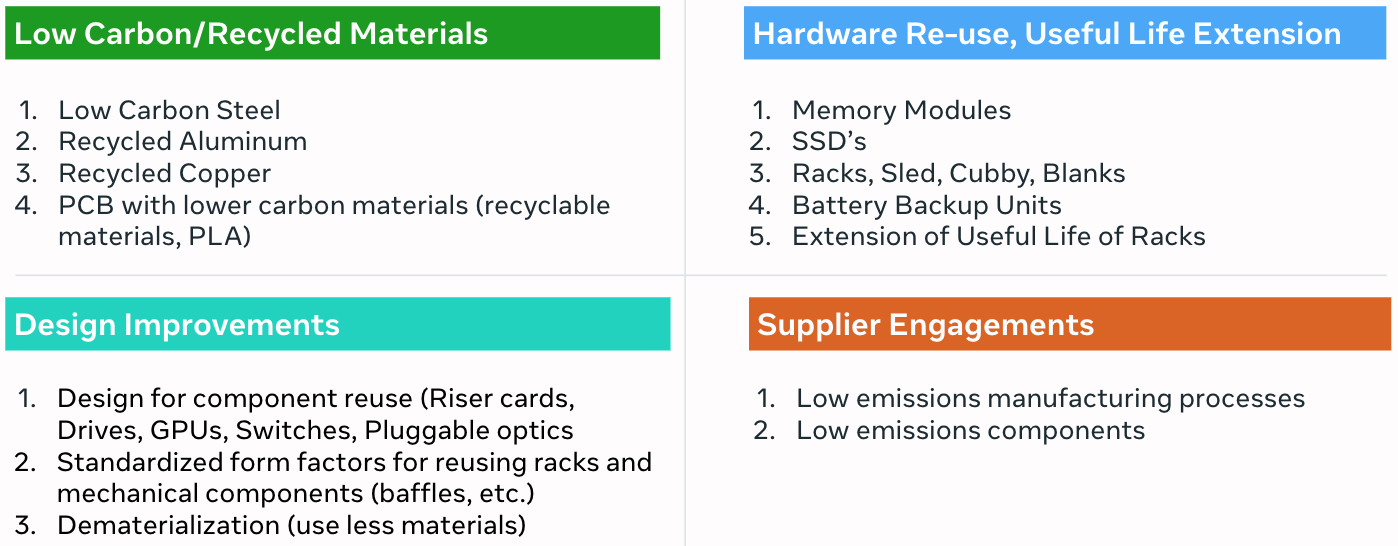

We focus on four main categories to address emissions associated with these hardware components:

We will cover a few of the levers listed above in detail below.

Modular Rack Designs

Modular Design which allows older rack components to be re-used in newer racks. Open Rack designs (ORv2 & ORv3) form the bulk of high volume racks that exist in our data centers.

Here are some key aspects of the ORv3 modular rack design:

- ORv3 separates Power Supply Units (PSUs) and Battery Backup Units (BBUs) into their own shelves.

This allows for more reliable and flexible configurations, making repairs and replacements easier as each field replaceable unit (FRU) is toolless to replace. - Power and flexibility

The ORv3 design includes a 48 V power output, which allows the power shelf to be placed anywhere in the rack. This is an improvement over the previous ORV2 design, which limited the power shelf to a specific power zone - Configurations

The rack can accommodate different configurations of PSU and BBU shelves to meet various platform and regional requirements. For example, North America uses a dual AC input per PSU shelf, while Europe and Asia use a single AC input. - Commonization effort

There is an ongoing effort to design a “commonized” ORv3 rack frame that incorporates features from various rack variations into one standard frame. This aims to streamline the assembly process, reduce quality risks, and lower overall product costs - ORv3N

A derivative of ORv3, known as ORv3N, is designed for network-specific applications. It includes in-rack PSU and BBU, offering efficiency and cost improvements over traditional in-row UPS systems

These design principles should continue to be followed in successive generations of racks. With the expansion of AI workloads, new specialized racks for compute, storage, power and cooling are being developed that are challenging designers to adopt the most modular design principles.

Re-Using/Retrofitting Existing Rack Designs

Retrofitting existing rack designs for new uses/high density is a cost-effective and sustainable approach to meet evolving data center needs. This strategy can help reduce e-waste, lower costs, and accelerate deployment times. Benefits of re-use/retrofitting include:

- Cost savings

Retrofitting existing racks can be significantly cheaper compared to purchasing new racks. - Reduced e-waste

Reusing existing racks reduces the amount of e-waste generated by data centers. - Faster deployment

Retrofitting existing racks can be completed faster than deploying new racks, as it eliminates the need for procurement and manufacturing lead times. - Environmental benefits

Reducing e-waste and reusing existing materials helps minimize the environmental impact of data centers.

There are several challenges when considering re-using or retrofitting racks:

- Compatibility issues

Ensuring compatibility between old and new components can be challenging. - Power and cooling requirements

Retrofitting existing racks may require upgrades to power and cooling systems to support new equipment. - Scalability and flexibility

Retrofitting existing racks may limit scalability and flexibility in terms of future upgrades or changes. - Testing and validation

Thorough testing and validation are required to ensure that retrofitted racks meet performance and reliability standards.

Overall, the benefits of retrofitting existing racks are substantial and should be examined in every new rack design.

Green Steel

Steel is a significant portion of a rack and chassis and substituting traditional steel with green steel can reduce emissions. Green steel is typically produced using electric arc furnaces (EAF) instead of traditional basic oxygen furnaces (BOF), allowing for the use of clean and renewable electricity and a higher quantity of recycled content. This approach significantly reduces carbon emissions associated with steel production. Meta collaborates with suppliers who offer green steel produced with 100% clean and renewable energy.

Recycled Steel, Aluminum, and Copper

While steel is a significant component of rack and chassis, aluminum and copper are extensively used in heat sinks and wiring. Recycling steel, aluminum, and copper saves significant energy needed to produce hardware from raw materials.

As part of our commitment to sustainability, we now require all racks/chassis to contain a minimum of 20% recycled steel. Additionally, all heat sinks must be manufactured entirely from recycled aluminum or copper. These mandates are an important step in our ongoing sustainability journey.

Several of our steel suppliers, such as Tata Steel, provide recycled steel. Product design teams may ask their original design manufacturer (ODM) partners to make sure that recycled steel is included in the steel vendor(s) selected by Meta’s ODM partners. Similarly, there are many vendors that are providing recycled aluminum and copper products.

Improving Reliability to Extend Useful Life

Extending the useful life of racks, servers, memory, and SSDs helps Meta reduce the number of hardware equipment that needs to be ordered. This has helped achieve significant reductions in both emissions and costs.

A key requirement for extending useful life of hardware is the reliability of the hardware component or rack. Benchmarking reliability is an important element to determine whether hardware life extensions are feasible and for how long. Additional consideration needs to be given to the fact that spares and vendor support may have diminishing availability. Also, extending hardware life also comes with the risk of increased equipment failure, so a clear strategy to deal with the higher incidence of potential failure should be put in place.

Dematerialization

Dematerialization and removal of unnecessary hardware components can lead to a significant reduction in the use of raw materials, water, and/or energy. This entails reducing the use of raw materials such as steel on racks or removing unnecessary components on server motherboards while maintaining the design constraints established for the rack and its components.

Dematerialization also involves consolidating multiple racks into fewer, more efficient ones, reducing their overall physical footprint.

Extra components on hardware boards are included for several reasons:

- Future-proofing

Components might be added to a circuit board in anticipation of future upgrades or changes in the design. This allows manufacturers to easily modify the board without having to redesign it from scratch. - Flexibility

Extra components can provide flexibility in terms of configuration options. For example, a board might have multiple connectors or interfaces that can be used depending on the specific application. - Debugging and testing

Additional components can be used for debugging and testing purposes. These components might include test points, debug headers, or other features that help engineers diagnose issues during development. - Redundancy

In some cases, extra components are included to provide redundancy in case one component fails. This is particularly important in high-reliability applications where system failure could have significant consequences. - Modularity

Extra components can make a board more modular, allowing users to customize or upgrade their system by adding or removing modules. - Regulatory compliance

Some components might be required for regulatory compliance, such as safety features or electromagnetic interference (EMI) filtering.

In addition, changes in requirements over time can also lead to extra components. While it is very difficult to modify systems in production, it is important to make sure that each hardware design optimizes for components that will be populated.

Examples of extra components on hardware boards include:

- Unpopulated integrated circuit (IC) sockets or footprints

- Unused connectors or headers

- Test points or debug headers

- Redundant power supplies or capacitors

- Optional memory or storage components

- Unconnected or reserved pins on ICs

In addition to hardware boards, excess components may also be present in other parts of the rack. Removing excess components can lead to lowering the emissions footprint of a circuit board or rack.

Productionizing New Technologies With Lower Emissions

Productionizing new technologies can help Meta significantly reduce emissions. Memory and SSD/HDD are typically the single largest source of embodied carbon emissions in a server rack. New technologies can help Meta reduce emissions and costs while providing a substantially higher power-normalized performance.

Examples of such technologies include:

- Transitioning to SSD from HDD can reduce emissions by requiring fewer drives, servers, racks, BBUs, and PSUs, as well as help reduce overall energy usage.

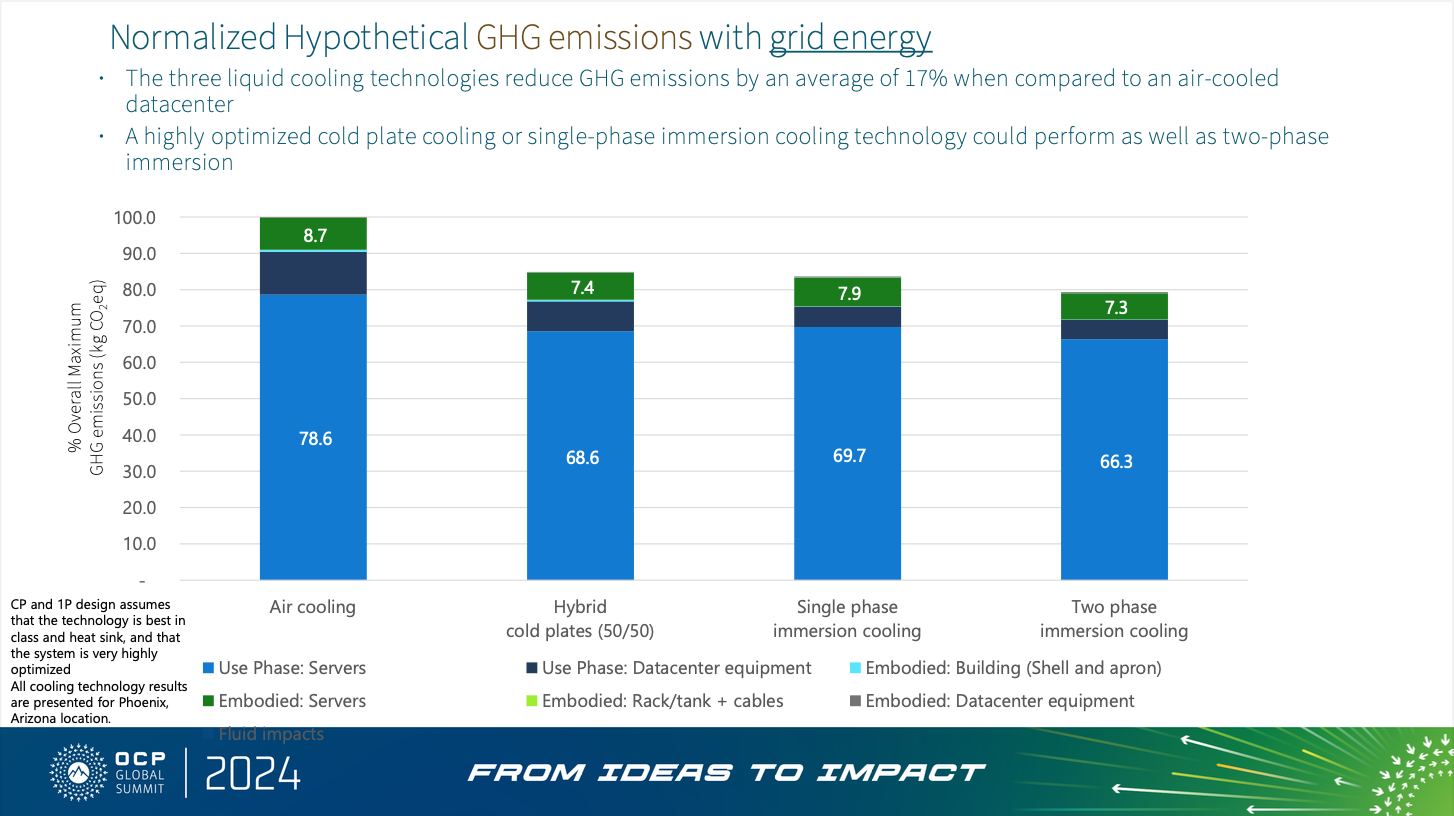

- Depending on local environmental conditions, and the data center’s workload, using liquid cooling in server racks can be up to 17% more carbon-efficient than traditional air cooling.

Teams can explore additional approaches to reduce emissions associated with memory/SSD/HDD which include:

- Alternate technologies such as phase-change memory (PCM) or Magnetoresistive Random-Access Memory (MRAM) that have the same performance with low carbon.

- Use Low-Power Double Data Rates (LPDDRs ) for low power consumption and high bandwidth instead of DDR.

- Removing/reusing unused memory modules to reduce energy usage or down-clocking them during idle periods.

- Using fewer high capacity memory modules to reduce power and cooling needs. Use High Bandwidth Memory (HBM) which uses much less energy than the DDR memory.

Choosing the Right Suppliers

Meta engages with suppliers to reduce emissions through its net zero supplier engagement program. This program is designed to set GHG reduction targets with selected suppliers to help achieve our net zero target. Key aspects of the program include:

- Providing capacity building: Training suppliers on how to measure emissions, set science-aligned targets, build reduction roadmaps, procure renewable energy, and understand energy markets.

- Scaling up: In 2021 the program started with 39 key suppliers; by 2024 it expanded to include 183 suppliers, who together account for over half of Meta’s supplier-related emissions.

- Setting target goals: Meta aims to have two-thirds of its suppliers set science-aligned greenhouse gas reduction targets by 2026 . As of end-2024, 48% (by emissions contribution) have done so.

The Clean Energy Procurement Academy (CEPA), launched in 2023 (with Meta and other corporations), helps suppliers — especially in the Asia-Pacific region — learn how to procure renewable energy via region-specific curricula.

The Road to Net Zero Emissions

The Design for Sustainability principles outlined in this guide represent an important step forward in Meta’s goal to achieve net zero emissions in 2030. By integrating innovative design strategies such as modularity, reuse, retrofitting, and dematerialization, alongside the adoption of greener materials and extended hardware lifecycles, Meta can significantly reduce the carbon footprint of its data center infrastructure. These approaches not only lower emissions but also drive cost savings, e-waste reductions, and operational efficiency, reinforcing sustainability as a core business value.

Collaboration across hardware designers, engineers, suppliers, and sustainability experts is essential to realize these goals. The ongoing engagement with suppliers further amplifies the impact by addressing emissions across our entire value chain. As Meta continues to evolve its rack designs and operational frameworks, the focus on sustainability will remain paramount, ensuring that future infrastructure innovations support both environmental responsibility and business performance.

Ultimately, the success of these efforts will be measured by tangible emissions reductions, extended useful life of server hardware, and the widespread adoption of low carbon technologies and materials.

The post Design for Sustainability: New Design Principles for Reducing IT Hardware Emissions appeared first on Engineering at Meta.

Login to comment

LoginRelated Conversations

-

How Meta Is Leveraging AI To Improve the Quality of Scope 3 Emission Estimates for IT Hardware

0 Replies

-

OCP Summit 2025: The Open Future of Networking Hardware for AI

0 Replies

-

10X Backbone: How Meta Is Scaling Backbone Connectivity for AI

0 Replies

-

Scaling Privacy Infrastructure for GenAI Product Innovation

0 Replies

-

Introducing OpenZL: An Open Source Format-Aware Compression Framework

0 Replies